CircuitMaker is not just a free EDA software tool from Altium, it’s also a community of creative people and design content, working together to invent circuits and electronics products for a better future.

Get inspired

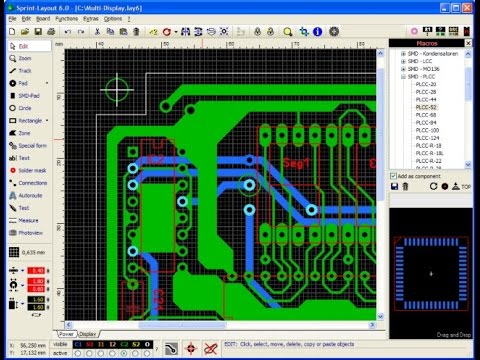

The.pcb file extension is also used for ACCEL or Protel printed circuit board files, P-CAD database files, PC-Doctor files, Broderbund Print Shop business card files and PCB Layout check design rule template files. Update info Upload example file PCB file openers, viewers, etc. These apps are known to open certain types of PCB files. TO USE 'SMART OPEN': From the Unisoft software click FILE from the main menu, click SMART OPEN and a new window opens. In the new window browse to and select the directory that your project CAD or Gerber files are located in. A new window opens and select one of the files presented and your PC Board will be displayed.

About circuitmaker

For turning great ideas into real products, you need design tools that won’t limit your imagination or hold you back. CircuitMaker has all the power you need to design high quality schematics and Printed Circuit Boards, with no artificial limits on layer counts or board area. Best of all it’s free.

Read Morefind & rate great design content

The CircuitMaker community is where you will find great reference designs, and be able to promote and rate other projects in the community.

You can even set up teams for collaborative design efforts.

WHAT MEMBERS ARE SAYING

Eli Hughes

Wavenumber LLC.

Open Pcb File Online

CircuitMaker is the 1st free PCB tool I have encountered that has features of a professional design tool. A tool that is backed by people who know EDA means that we can finally have something for those of us who want to get things done without being obstructed by complicated installation, a horrible user interface or a mess of a library system. Couple this with that fact that making is also about collaborating and sharing. The folks at CircuitMaker have unique vision about creating a platform, not just a barebones tool for those who aspire to be “mad engineers”.

Roberto Lo Giacco

Professional Engineer

Finally some fresh air in the EDA market: a modern interface with some really pro capabilities and no serious limitation. This is the tool any electronics maker was waiting for and it is community focused.

Nicholas Rabault

The Poppy Project

Poppy is an open-source platform for the creation, use and sharing of interactive 3D printed robots. We love CircuitMaker because it offers the possibility of our community to contribute easily. We can promote our board model by sharing a simple link to a release. Users can produce themselves our design directly or by forking it to adapt it to their needs. Mechanical integration is a really important factor in robotics so the 3D modeling in CircuitMaker enables that.

Design the next

great electronic product

POWERFUL ECAD FOR OPEN SOURCE HARDWARE

We think you deserve better design tools, made specifically for you, to turn great ideas into reality. That’s why we’ve created CircuitMaker. Besides being a collaborative community for electronic design content, CircuitMaker is Schematic & PCB design software, built upon Altium Designer technology. With a streamlined interface and powerful engine to boot, you’ll never have to worry about your software holding you back. This is a free design tool unlike anything you’ve seen before.

UNLIMITED & FREE

Typically, free EDA software is poorly developed, or has restrictions on design size that render it useless for any real project. Not CircuitMaker - you get the full power of 16 signal + 16 plane layers, and no restrictions to the PCB dimensions. You can even make money with your designs, because there’s no “non-commercial” clause!

MASSIVE, RICH COMPONENT LIBRARY

CirucitMaker is built on a community library with hundreds of thousands of components - all backed by the awesome Octopart database. Placing components in CircuitMaker designs is as easy as searching by manufacturer part number or by design parameters. You can also add your own custom parts and mechanical components too.

SHARE & COLLABORATE

You can create projects with teams in the CircuitMaker Community, and allow other community members to work with you on the design. Harness the power of teams to get projects done faster! Released designs can be forked and then modified so you can build new designs with different features without having to start from scratch every time.

NATIVE 3D™

Altium Native 3D™ technology means that when you’re in the PCB editor, just hit the 3 key and you can immediately see the PCB layout in full 3D. It will also show any component clearance violations and you’ll even know what the overlap distances are, so you can get your designs right - and to fit the box - the first time.

ONE-CLICK MANUFACTURING

Once you have finished your design, you can release the project to the community. From there you can download the gerbers and send them off to any PCB manufacturer. But even easier than that, we’ve partnered with select manufacturers to provide a one-click manufacture button that can directly send your board for quoting - either bare board prototype or full PCB fabrication and assembly, at the best possible price. It’s up to you!

PUSH-N-SHOVE ROUTING

For a tool we’re giving away for free, we did not hold back on the push and shove routing capabilities! The interactive routing modes include obstacle avoidance, hug, hug-n-push, and obstacle ignore. The push modes will push other trace and vias, as well as hop-over. You can even route differential pairs and interactively add accordions to nets that need that extra length for signal delays.

MULTI-SHEET SCHEMATIC EDITOR

CircuitMaker uses the same easy-to-use and great looking schematic editor Altium is known for. You can even do complex multi-sheet designs, and use hierarchical design blocks, and generate SmartPDF™ outputs from your project.

TOPOLOGICAL AUTOROUTER

The Situs™ topological autorouter works in concert with your design rules to help you get the board done fast. With BGA and SMT fanout, parallel memory, hug, and via optimization, it’s easy to use Situs to get working results really fast. You can also interactively route multi-nets or single nets, or use manual routing with auto-complete.

DRC/DFM VALIDATED OUTPUTS

When you’re ready to turn your design into a real board, CircuitMaker will generate industry standard CAM outputs. You can choose Gerber and NC Drill, or ODB++, or both. IPC test point reports and all other necessary outputs for professional manufacturing can be generated as well, and all this through a succinct release process that ensures your board passes design rules checks for DFM and assembly.

IMPORT DESIGNS FROM OTHER TOOLS

CircuitMaker comes with a huge set of importers, including OrCAD™, PCAD®, PADS®, EAGLE™, Protel and more - so starting your project from a manufacturer reference design is easy. The importers support both PCB and Schematic documents.

Printed Circuit Boards (PCBs) are backbones of electronic devices and equipment. The increasing density of circuits and decreasing size trend of electronic products lead circuit boards to develop into higher complexity. Holes or vias, responsible for electrical connections between layers and corresponding functions a board will implement according to design requirement, won't effectively work unless they are suitably designed or manufactured. For unsuitable manufacturing, it can be easily solved by selecting a reliable PCB manufacturer. The solution to the other issue, that is, unsuitable design, depends largely on circuit board design engineers who have to create integrated and reliable design files based on which PCB fabricators carry out manufacturing.

It's believed that NC drill file generation has been plaguing most PCB design engineers for a long time. Therefore, it's necessary to summarize design guidelines based on leading PCB design software.

NC drill file, short for numeric control drill file, refers to a type of file regulating all the information concerning hole or via drilling requirement including tooling size, hole size and location. A sample NC drill file is shown below;

It's of significant necessity for PCB design engineers to create NC drill files since a lot of trouble can be avoided when PCB files are converted into NC drill files and Gerber files. Nevertheless, the factual situation is that a number of engineers tend to send PCB files directly to PCB manufacturer without converting them into NC drill files or Gerber files. They have been used to finishing PCB design files or exporting the design files from PCB cloning software and sending them to circuit board manufacturers.

The ordinary workflow is that after receiving PCB design files, board fabricators have to transform them into NC drill files and Gerber files before manufacturing. Because electronic engineers working in PCB fabrication house understand printed circuit boards from a completely different perspective from PCB engineers do. The generated Gerber files may not be what PCB designers expect. For example, some PCB design engineers would like to define component parameters in design files but they don't want the information to be shown on the final product. If this point fails to be indicated by PCB design engineers, those information will be left on end product with possible scrap generated. Furthermore, in the process of Gerber files generation, some issues or indefinite aspects may be caused due to software version differentiations.

Therefore, the Optimal Solution is that PCB design engineers should convert their design files into Gerber files with NC drill files created as well that will then be sent to PCB manufacturers, based on which unnecessary trouble can be avoided.

NC drill files can be generated by nearly all PCB design software with its ordinary format as Excellon that was originally a manufacturer of CNC (Computer Numerical Control) systems for drillers and routers. Owing to its long life and active role in PCB drilling and routing equipment, Excellon has been accepted and coined as a set of industry standards.

Excellon is widely applied for standard CNC drilling and routing as it is capable of specifying machine definite info such as drill feed and speed.

In the main interface of Altium Designer, click File>>Fabrication Outputs>>NC Drill Files sequently and come to NC Drill Setup dialogue in which options need to be specified including NC Drill Format, Leading/Trailing Zeroes, Coordinate Positions etc.

Units of data in NC Drill Files can be either inches or millimeters that should be compatible with that of Gerber Files.

When it comes to Format, 3 selections are available: 2:3, 2:4 and 2:5 among which 2:3 features the lowest resolution whereas 2:5 features the highest resolution. Prior to deciding which format, it's necessary to consult your contract PCB manufacturer to determine whether which format is compatible with their manufacturing level.

Zero suppression drives NC Drill Files to be fit and neat and relies on PCB designers' application habits and convenience. When Suppress leading zeroes is picked, starting zeroes will be removed while when Suppress trailing zeroes is picked, ending zeroes will be removed.

Coordinate Positions contain two alternatives: absolute origin and relative origin, either of which should be chosen according to PCB designer's specific requirement. Moreover, it should be the same as Coordinate Positions regulated in Gerber Files.

Other items can be picked if necessary for projects. With all items determined, press OK to generate NC Drill Files that will be saved in the default path of sub-folder under the folder containing Project File.

How to Generate NC Drill File by Cadence Allegro (OrCAD)?

Different from Altium Designer, the default format of NC Drill Files exported by Cadence Allegro is not Excellon's. Therefore, prior to real generation of NC Drill Files, it's necessary to set concerning parameters by clicking Manufacture>>NC>>NC Parameters to enter NC Parameters dialogue.

In NC Parameters dialogue, items of Output file and Excellon format need to be determined. When it comes to Code in Output file, it's generally accepted that ASCII is picked since it is regarded as a newer type of code compared with EIA.

To generate an NC Drill File with a format of Excellon, it's necessary to click before Enhanced Excellon format.

For zero suppression, it's necessary to click before Leading or Trailing zero suppression based on PCB designer's project needs and demand or just in order to be in conformance with Gerber Files.

After items' determination, click Close button and NC Parameters dialogue will be escaped.

Then comes NC Drill dialogue by clicking Manufacture>>NC>>NC Drill.

Software To Open Pdb File

After finish determining items in this dialogue, press Drill to end up Drill Files generation. The created NC Drill Files can be found in the default file folder.

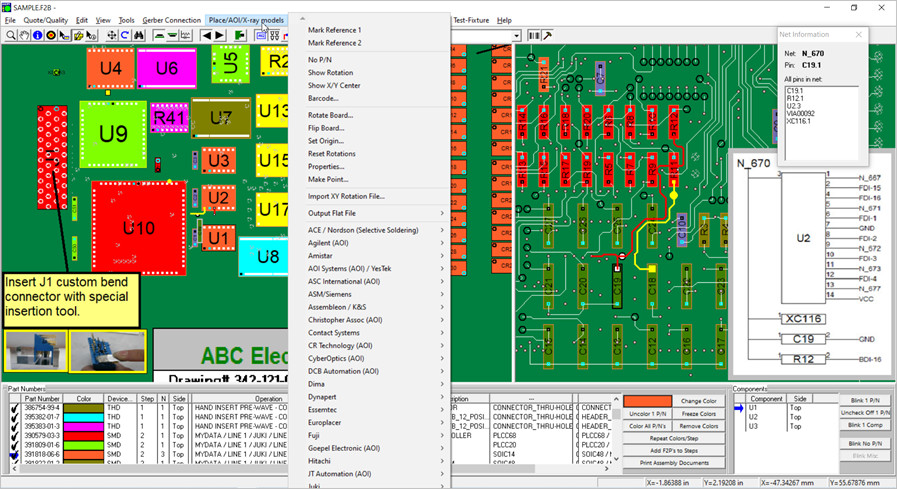

To generate CAM output from PADS software, open PCB design file in PADS and click File>>CAM>>Define CAM Documents sequently.

When it comes to a drill layer, select it and click Edit whereas for layers with no demand of drilling, directly click Add.

In Edit Document dialogue window, press Drill and Device Setup button to specify format of NC Drill Files in NC Drill Setup window.

To specify format of NC Drill Files, first press Excellon button at the left top of this window.

Pcb File Format

Software To Open Pcb File Online

In this window, you can see lots of items that are similar to those discussed in previous PCB design software. For Output Type, select ASCII. For Units, Zero Suppress and Coordinate, pick up the corresponding one. With these completed, press OK button.

Different PCB design engineers hold different preferences to their applied software so that they have to conform to different methods of generating NC drill files to fulfill requirement and demands of PCB fabricators. Although different PCB design software differ from each other in terms of NC Drill Files exporting, there's a cure-all rule that parameters applied in NC Drill Files must be compatible with those in Gerber Files so that reliability of end products will be greatly enhanced and strengthened.

Next articleHow to Generate Gerber Files based on Different PCB Design Software